Delta P & Delta-T in HVAC Systems

The concepts we hear revolving around the best practices in the HVAC industry all have their place in conversation when it comes to proper sizing, building management, heat-exchanger materials, piping systems, venting, and everything in-between. In our blog series at Patterson-Kelley we attempt to demystify much of the jargon surrounding the industry and hope that it helps everyone understand the foundation of HVAC systems. In this blog, we are going to look at one word that we have all heard and used before; Delta.

Delta Who?Delta, simply put, is a mathematical term that shows the difference between two varying factors. When added to letters such as Delta-T and Delta-P (the Delta sometimes designated by a triangle) we are exploring the difference in temperature (Delta-T) and the difference in pressure (Delta-P). The letters representing the first letter in the word, respectively. The temperature and pressure in question is where the explanation becomes more catered to the HVAC industry.

Calculating Delta-T

The Delta-T is calculated by finding the difference between the return air temperature and supply air temperature. Air temperature going in versus air temperature going out. The resulting temperature can highlight issues that may be plaguing a heating system.

Monitoring these Delta-T levels consistently can help educate you to see if there is any unnecessary energy usage or equipment failures to help you seek out any heating system issues that need to be addressed. There is immense importance to keep proper air temperature levels when maintaining any HVAC machine. Lower levels of differential temperature may indicate poor system performance, an excessively small difference between the incoming and outgoing temperature, and deficient capacity. Alternately, a higher differential pressure may signal faster water evaporation inside the unit.

Delta-P within Heat Exchangers

Much like Delta-T, Delta-P refers to the difference in air pressure in the system, although this concept can be a little trickier as it can change over time and provide trends within specific systems. It can also be applied to different areas within the system such as piping systems, heat exchangers, etc. Depending on the type of information being collected, the Delta-P in the heat exchanger can be calculated by subtracting the inlet pressure by the outlet pressure. Inlet pressure representing the air entering the inlet suction pipe and outlet pressure being the air leaving the unit located in the outlet exit pipe.

Delta-P within Piping Systems

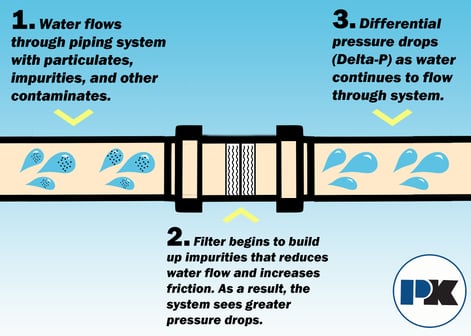

To illustrate differential pressure in the case of Delta-P, consider the following… One example of air pressure variability that can occur would be inside the pipes of a heating unit.

Commonly, heating systems will contain a filter or straining unit inside the pipes to assist water flows and maintain healthy air pressure levels. The function of the filter is to obstruct any solids, particulates, or contaminates from flowing downstream inside the water flow.

Depending on the filters specific construction, a certain quantity of these impurities will be captured by the straining unit resulting in higher friction and consequently; increased differential pressure (Delta-P). This will indicate that your filter is due for a service because it has collected an abundance of these previously discussed particulates that are now generating pressure drops in your piping system.

(See graphic below for showcase of an example of pipe system water flow and Delta-P drops.)

Again, the importance of calculating your pressure drops in all systems is paramount to your HVAC equipment’s health. To find Delta-P in your piping systems, subtract the inlet pressure from the outlet pressure. Doing so will provide you with the information needed to determine if your filters in your piping system may need maintenance.