With today’s technological landscape evolving and adapting to increasingly rapid expansion, Patterson-Kelley (PK) wants to dive deep into our standard touch-screen boiler interface; the NURO®. Considering building integration, IoT Protocols, and increased competition within the user platform market, this three-part blog will demonstrate the advanced abilities of our revolutionary controller in its current state and what it has in store for the future.

With today’s technological landscape evolving and adapting to increasingly rapid expansion, Patterson-Kelley (PK) wants to dive deep into our standard touch-screen boiler interface; the NURO®. Considering building integration, IoT Protocols, and increased competition within the user platform market, this three-part blog will demonstrate the advanced abilities of our revolutionary controller in its current state and what it has in store for the future.

In 2014, PK integrated the NURO® Touchscreen Controller to its entire line of products, applying the NURO® as a standard feature on all products able to equip the controller and replacing the existing MCBA and Envi® controllers. Due to growing demands within the industry and advancement in technology, PK was able to develop a control system that better-accommodated needs and desires, while more importantly, an entire system that controlled the response of the equipment while increasing efficiency.

The NURO® was developed by in-house engineers on a Linux based operating system. This allows updating and improving the control platform quickly and easily, using language that best fits PK equipment. Complete control of the boiler/water heater through the NURO®, down to selecting Fahrenheit or Celsius operation, grants users and servicers the ability to control their application best.

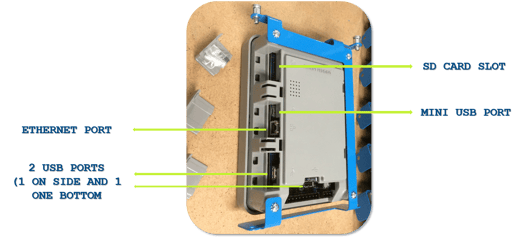

There are stark differences, setting the NURO® apart from previous controls, including a 7” color touchscreen, mini-processor embedded on the controller, 2 USB ports, Ethernet port, Mini USB port, and SD card slot. These ports allow the NURO® to have complete connectivity to the boilers they are equipped on, giving users the ability to download data and monitor the system performance directly or remotely, a task that was either impossible or would have taken months manually to perform.

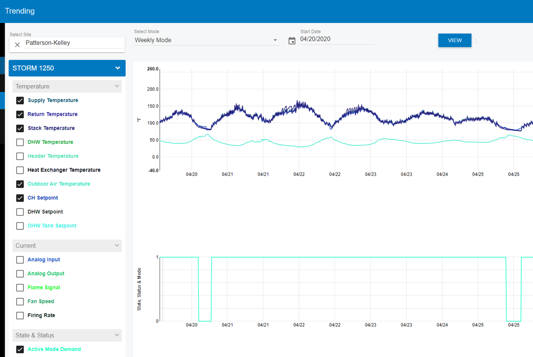

The Ethernet port can be used to integrate appliances into the NURO® CONNECT network, where one can remotely monitor equipment and view trending data points of its operation at a glance. This type of data was not only difficult to produce before computer monitoring, but time-consuming, as there had to be a person on-site to monitor trends, cycles, and common issues. USB ports can be used to download the parameters set on the appliance for future implementation and analysis by simply using a flash-drive to obtain data from the equipment for external storage. The USB ports also allow for the attachment of peripherals, such as a mouse and keyboard to make interface interaction easier for some users. The SD card slot is used to locally store trending data for the appliance to better analyze the performance and log any system alarms that may occur.

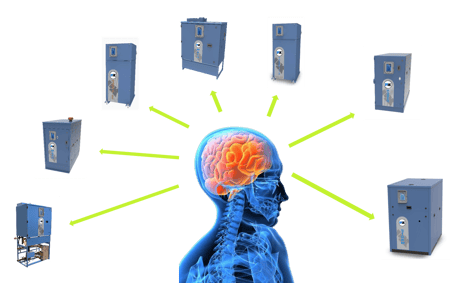

The touch-screen system can be seen as the brain of PK’s boilers, not only providing crucial data points about the system as it functions but in-depth views into critical operations for best efficiency and longevity of the boiler it is attached to. Algorithms set specifically for the equipment it is installed on, designed by our in-house team, allow for predictions in response based on the size of the appliance as well as its programmed operating characteristics. Embedded micro-processing allows for this transition to be seamless for all of the equipment. This also allows for easy integration of relayed devices such as pumps, valves, and sensors. Cascading controls are also embedded allowing for up to 32 boilers control through one master/member relationship.

Field servicing of NURO® connected boilers can be facilitated through a connected application available on iOS and Android stores. Connected boilers can be diagnosed remotely if a condition were to occur so that the proper maintenance can be performed both quickly and effectively. While this mitigates time and money spent, it is only an overview of what the NURO® Touch Screen Control System is capable of. In Part 2 of the NURO® Blog, we will examine what truly sets this controller apart from others in the field, while demonstrating how this technology can still be built upon in future iterations.