Examining Direct Fired Water Heaters

It comes as no surprise that technological advances in the water heating industry have allowed manufacturers to develop highly efficient commercial boilers that provide well rounded heating comfort. Utilizing commercial boiler platforms to produce both building heat and domestic hot water has become a trend in the industry, but what does this mean for the commercial units?

Using your boiler to produce domestic hot water can decrease the life of the heat engine if adverse water conditions are not taken care of. Typical hot water boiler installations achieve peak efficiencies during the shoulder months of the year, when the boiler is operating consistently to produce both comfort heat and domestic hot water. However, during the warmer months the commercial boiler is forced to operate only when domestic hot water is required. Both, varying water loads and varying temperatures, can become hard to control and cause thermal shock on the direct fired appliance. Additionally, in this configuration, the heat exchanger can be exposed to adverse water quality. If proper water treatment is not applied, high levels of scale and corrosion can shorten the life expectancy of the engine.

Why Separate Your Boiler from Your Hot Water System?

Indirect water heaters have played a prominent role in the HVAC industry. These water heaters use an external heat source, like a boiler, to produce domestic hot water to fixtures in the building. The water heater is connected to the boiler through a closed water loop, allowing the hot boiler water to travel between the boiler’s heat engine and the indirect hot water heat exchanger, separate from the domestic water loop. This configuration prevents hard water from reaching the highest temperature heating surface (the boiler heat engine) which extends the life of both heating systems through the mitigation of rapidly changing temperatures reaching the boiler equipment directly and reducing thermal shock.

The efficiency of an indirect water heater depends on the effectiveness and efficiency of the external heat source. Indirect water heaters do not require an additional source of fuel for operation, simplifying gas connections in your building. Additionally, multiple heat exchangers can be attached to one boiler heat engine to achieve different operating temperatures and accommodate varying loads. The surface area on the heat exchanger can also be extended to allow lower boiler fired temperatures, increasing your potential to condense in any operating mode and maximizing condensing boiler efficiency.

P-K Solutions

P-K Solutions

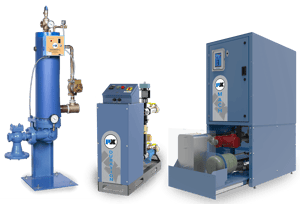

A combination of a high efficiency commercial boiler and an indirect water heater can be a long-lasting investment. Patterson-Kelley offers multiple options that support indirect water heating and can extend the life of your heating system.

The P-K MACH® ‘n’ Roll condensing indirect water heater produces both domestic hot water and comfort heat. This unit separates the domestic hot water from the boiler’s heat exchanger by including an indirect heat exchanger section. This combination maximizes the life of both systems.

The Duration™ III Pumped Package is a great option for indirect water heating and can be seamlessly added to any other P-K comfort heat system. Installing a combination of multiple Duration™ III units can be a great fit for buildings that require varying loads and different temperatures. The P-K Compact® and Duration™ III Instantaneous are perfect fits for large boiler loops and can be easily activated in zones that require domestic hot water.

Want to learn more about indirect water heating? Contact your Patterson-Kelley local Representative today or Join us at the ASPE Convention & Expo!