With efficiency becoming a factor in the basis of design of new construction buildings, HVAC manufacturers have to consider how a heat exchanger controls the combustion to ensure the unit is condensing at an efficient rate. We can also ask how does a unit know what is the correct mixing ratio to make the most efficient package? What controls need to be put in place to analyze the combustion so dynamic adjustments can be made to varying load conditions? These are important questions without uniform answers. The key is ensuring that the unit can maintain its air and fuel balance, without introducing an excess of either one. This is achieved mechanically or electronically.

With efficiency becoming a factor in the basis of design of new construction buildings, HVAC manufacturers have to consider how a heat exchanger controls the combustion to ensure the unit is condensing at an efficient rate. We can also ask how does a unit know what is the correct mixing ratio to make the most efficient package? What controls need to be put in place to analyze the combustion so dynamic adjustments can be made to varying load conditions? These are important questions without uniform answers. The key is ensuring that the unit can maintain its air and fuel balance, without introducing an excess of either one. This is achieved mechanically or electronically.

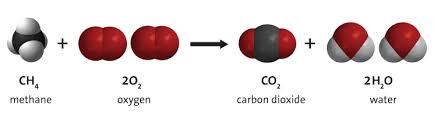

Perfect combustion occurs when the proper mixture of fuel and oxygen under precise conditions is consumed completely in the process. This precise amount is called the stoichiometric point of the fuel. Combustion that is not complete leaves partially unburned fuel in the form of waste. Carbon Monoxide and Hydrogen are 2 common waste products. Natural Gas, the most common combustible in Patterson-Kelley equipment, is made up of predominantly Methane. Its by-products are CO2 and H20. Due to this makeup, the theoretical air/fuel ratio that is needed for complete combustion of Carbon and Hydrogen is 9.53:1. The resulting heat that is released is known as its heat of combustion.

It has been long recognized that controlling excess air in the combustion process is vital to the safe and efficient conversion of fuels to useful energy. This can be achieved by pre-combustion control, or post-combustion control, meaning the process happens before or after combustion, respectively.

Advancements in technology have allowed systems to measure the oxygen present in exhaust gasses and readjust the fuel and air mixture to correct for deviation from the set oxygen level of the flue gas from the boiler. This is a process known as oxygen trimming (O2 Trim) which is utilized in post-combustion controls. While this is an improvement over previous methods, a correction only occurs after excess oxygen is detected and the excess has already promoted waste. This process also presents another part of the appliance that needs to be replaced during annual maintenance as well as calibration with heat cycles to ensure peak efficiency operation: the O2 sensor.

In large boiler systems, pre-combustion controls have been developed by adding metering of fuel and air. This occurs before errors happen, making it superior to post-combustion control. Patterson-Kelley achieves this form of control through a simple custom-designed venturi-based system, utilizing readily available zero governor gas valves for pre-combustion fuel-air control that maintains oxygen levels +/- .05% of the target 5% oxygen across the complete firing range. This valve responds to this normalized air pressure at a 1:1 ratio and can precisely meter fuel to the combustion process before combustion occurs. This ratio control, unlike what an O2 trim system would require, is done without multiple motors or linkage. There are fewer moving parts overall minimizing burner system maintenance while maintaining efficient, reliable, and repeatable combustion.

For more information on achieving perfect combustion, read our white paper here Achieving Perfect Combustion.