In our last blog, we discussed the NURO® Touch-Screen Controller at a high level. We looked at some of the time and cost-saving capabilities of using the NURO® platform to integrate between the boiler/water heater and the building’s needs, and some of the physical aspects of the advanced controller. In Part 2 of this series, we want to dig a little deeper into some of the capabilities that differentiate the NURO® from other boiler controls on the market.

In our last blog, we discussed the NURO® Touch-Screen Controller at a high level. We looked at some of the time and cost-saving capabilities of using the NURO® platform to integrate between the boiler/water heater and the building’s needs, and some of the physical aspects of the advanced controller. In Part 2 of this series, we want to dig a little deeper into some of the capabilities that differentiate the NURO® from other boiler controls on the market.

The night setback feature on the NURO® is a crucial part of the controller’s scheduling capabilities. This feature reduces the active set-point by a fixed amount when the building is unoccupied. While enabled the set-point can be altered, known as the Night Setback Amount, which is the temperature subtracted from the active set-point when the building is empty. The feature exists for the user to configure a weekday / time schedule when the building is utilized and when it is not, based off of a 7-day week. This ultimately saves in heating cost as there is no unnecessary heat going into the building during its off hours.

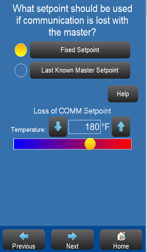

The NURO® Cascading ability gives the user the option to operate multiple boilers under different parameters using the controller. The cascade selection defines the role of the boiler in multiple unit system. The “cascade master” is the boiler acting as the primary device in the system, while subsequent devices are known as “cascade members”. The common set-point is when each cascade member boiler will generally have the same outlet temperature but not necessarily the same firing rate. This setting is normally used if the boiler will have variable flow through it as in a primary only system with isolation valves. With the common firing point, each cascade member boiler will generally have the same firing rate but not necessarily the same outlet temperature. This setting is normally used if the boiler will have constant flow as in a primary secondary pumping system. In addition to these adjustable capabilities one can adjust firing rate or temperature at which cascaded units enable and disable, as well as the time that needs to elapse to bring another boiler online. This will significantly reduce the potential for short cycling of equipment, a large leader in system inefficiencies.

Not only can the NURO® control your comfort heat load, it can enable and disable the equipment based on a hot water demand as well. The Domestic Hot Water (DHW) Priority Wizard can allow your boiler to bring hot water to your showers, sinks, and many other fixtures within your building. This can be enabled either by Aquastat, or temperature sensor, on/off function, or operate under remote modulation. You can cater to varying differential temperatures that the unit engages and disengages the equipment from its sensor location (storage tank or system header) as well as at what temperature the boiler will and can fire to based off of pre-determined limits, all in 3 simple and straightforward screens on the user interface. An example of this is the “DHW STAT / SENSOR” terminals. When the tank temperature drops below DHW TANK SETPOINT minus DHW TANK DIFFERENTIAL ON, a demand for DHW mode operation is created, and the boiler will PID modulate to the DHW BOILER SETPOINT. When the tank temperature exceeds DHW TANK SETPOINT plus DHW TANK DIFFERENTIAL OFF. This ability maximizes the efficiency of the system and its operations in both comfort and domestic load profiles.

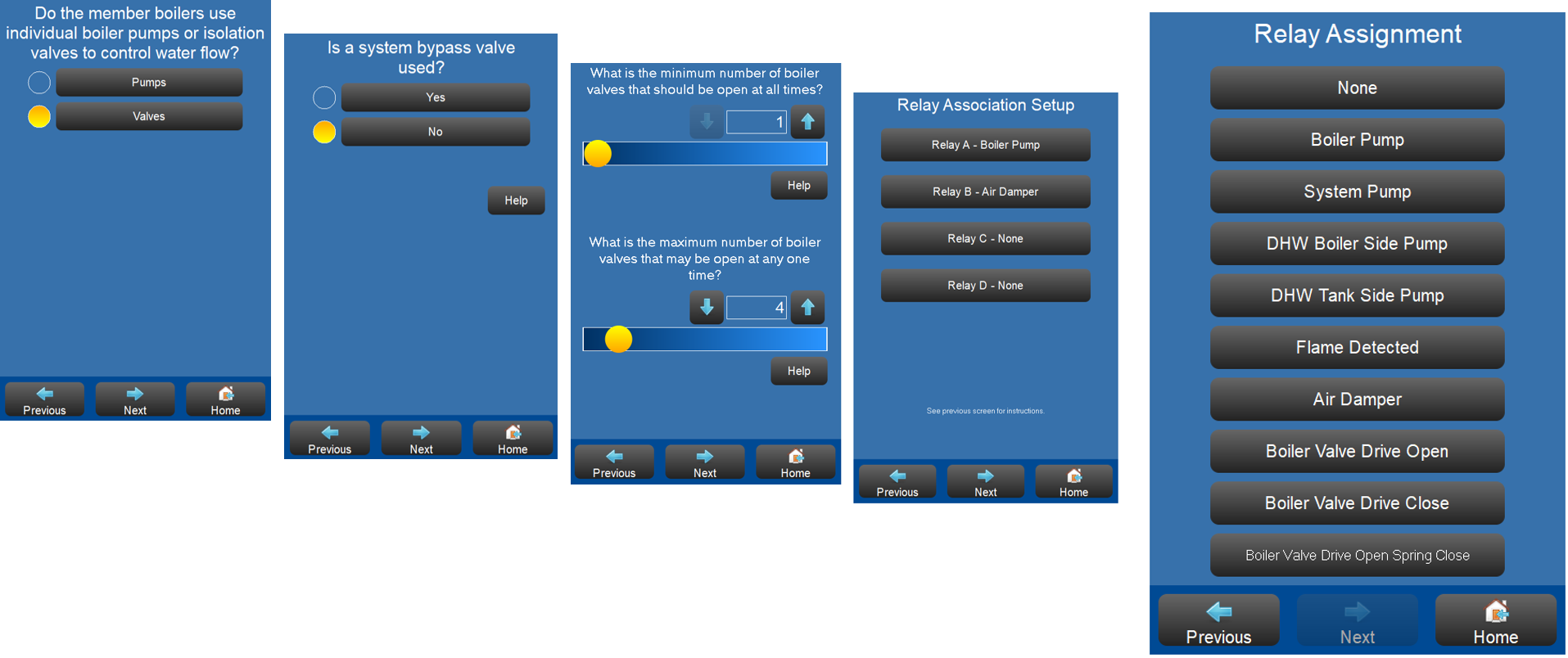

Another powerful feature of the NURO® control are the four configurable output relays, located on the high voltage TB2 terminal block. Relays A through D can be configured to operate an ever-expanding list of devices including the Boiler Pump, System Pump, Air Damper, Motorized Control Valve, as well as contact relays to show items are enabled to your greater building management system. An example of these such relays are verification a cascaded boiler is enabled, the position of a bypass valve in a primary only system, or if night setback is enabled. In addition to this there are virtual relay options that can operate essentially any function one would want enabled via firing rate, temperature, or signal through the NURO® controller. These virtual relays can be tied in parallel to another relay for operation such as dual pump operation to maximize the capabilities of your overall boiler / DHW system.

The PK NURO® has many additional capabilities to what we have shown, but this will give you an idea of the breadth Patterson-Kelley has developed into our controller to paint a picture of what we envision our equipment to handle. Patterson-Kelley has designed a platform to not only best control your boiler or water heater internally, but given the capability to adapt to the environment around our appliances to maintain maximum efficiency. We have also built in capabilities to control equipment near to our units to best control the system our appliances are attached to.

In Part 3 of the Patterson-Kelley NURO® series, we look at the upcoming iteration of the NURO®, the NURO® 2.0 and the capabilities it will offer.

For more information, go to https://www.pattersonkelley.com/solutions/controls/nuro/